The Sunday News

Dumisani Nsingo, Senior Business Reporter

ONE of the country’s oldest manufacturers of ceramic and refractory products, Dete Industrial Ceramics in Hwange District, Matabeleland North Province is seeking a strategic partner to assist it in turning around its waning fortunes.

Dete Industrial Ceramics board chairman Mr Brian Mushohwe said the company was operating at its lowest ebb due to lack of adequate working capital.

Dete Industrial Ceramics is wholly owned by Ginhole Investment, which is a subsidiary of the Industrial Development Corporation (IDC).

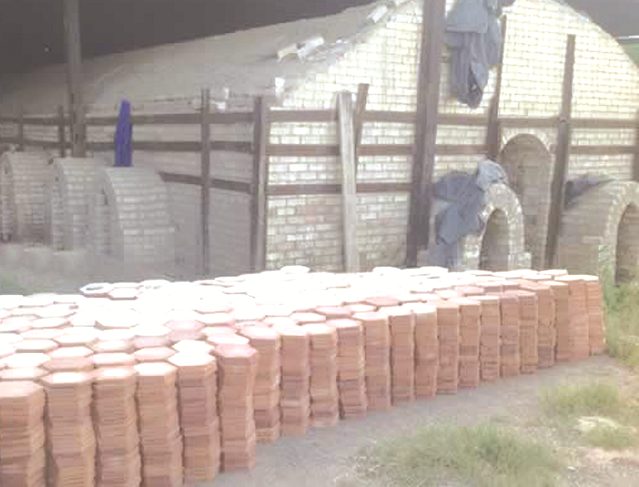

The company is into manufacture of ceramic or re-factory products like bricks, tiles, furnace jackets, pavers through a re-factory plant, tourism and hospitality through a safari lodge and hotel all in Dete, Hwange. It has a bakery, service station and green garden all for servicing the local community.

“Production of late has been very low with batches of bricks and tiles being produced and marketed by the company. Capacity utilisation is, however, below 15 percent due to lack of working capital as well as old equipment which is prone to breakdowns,” said Mr Mushohwe.

He said there was also a need to replace the plant’s archaic machinery with modern technologies so as to enhance efficiency and production.

“A new semi-automated plant as well as capacitation in clay digging (mechanised rather than current manual) to increase raw material availability would help enhance production considerably.

“About $1,5 million will be required for this retooling. The company is looking for investors or partners with capacity to help upgrade, expand and modernise the business,” said Mr Mushohwe.

Dete Industrial Ceramics started operating in 1989 and the company used to be a major supplier of refractory or fire bricks. Its biggest customers were mostly iron smelting companies notably Ziscosteel, which it was supplying with fire bricks for the relining of its furnaces.

Due to depressed business, the company has over the years been forced to retrench part of its workforce from a high of 200 in 2007 to only 20 employees to date.

However, Mr Mushohwe said prospects of the company turning around its fortunes were high considering the massive infrastructural development projects earmarked in Matabeleland region and in various parts of the country.

“Harare and Bulawayo have been good markets for the limited production done by the company at present. With more production there is scope to increase supply given huge residential developments in the two cities.

Hwange, Lupane and Victoria Falls are also increasingly taking products that the company is producing,” he said.

The company has over the years received a number of enquiries on the export market.

“There are export customers in Botswana and Zambia that we have supplied in the past who can be better served if production can be increased,” said Mr Mushohwe.-@DNsingo