The Sunday News

Munyaradzi Musiiwa, Midlands Correspondent

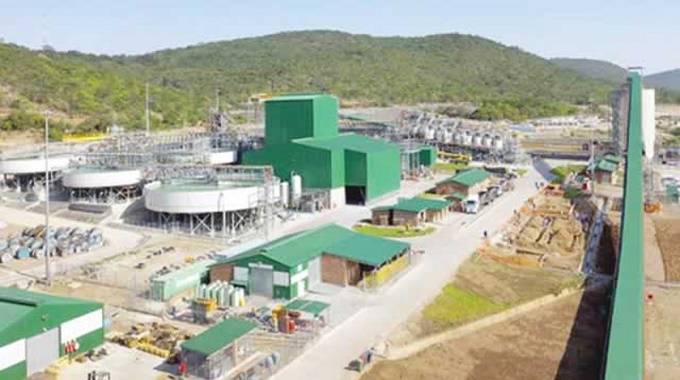

ANGLO-American Platinum Zimbabwean unit, Unki Mine in Shurugwi has procured a mobile Polymerase Chain Reaction (PCR) testing laboratory for coronavirus as part of its multifaceted intervention strategies in fighting the disease as well as ensuring safety of its employees and surrounding communities.

PCR test is the standard for Covid-19 testing. Unki Mine safety, health, environment and quality manager Mrs Betty Dube said the platinum miner has already procured the mobile laboratory and was finalising on the registration and importation papers.

Mrs Dube said PCR testing was one of the company’s priorities to ensure the safety of its workers.

“In case of a suspected case we have come up with what we call a trigger action response plan. We will look at people who have symptoms either at the mine entrance, workplace or the residential area and tell them what to do until the district rapid response team arrives to further investigate the patients. We have future on sight Covid-19 management strategies.

“This pandemic is new and we learn new things every day from different organisations. However, as a mine we have acquired a (mobile) testing laboratory which will be doing PCR testing for Covid-19. We are just finalising on the paperwork on the importation. Once we are done with the paperwork, we will be able to do on sight testing. We have prepared a place for the container. It is fully equipped. This will enable us to give people help instantly and test them on time,” she said.

Unki Mine general manager Mr Walter Nemasasi said the mine would start testing in the next two weeks.

“At the moment we are doing temperature tests but we are bringing in a mobile laboratory which will enable us to do PCR testing for Covid-19 and that should be in the next fortnight,” he said.

Mr Nemasasi said the company had also experienced the ripple effects of Covid-19 which slowed down production.

“Initially we remained with critical staff but on April 7 we brought back about 600 workers and now we are around 1 000. We are still trying to figure out how best all the 3 000 employees can remain working. We may have 50 percent on sight while some are working from home.

We are still paying all the 3 000 their salaries. We are still trying to understand what our constraints and capabilities are. We are very clear that it is not going to be the same. We are also looking at continuous working shifts,” he said.

Mr Nemasasi said the company was also working on operating on full capacity soon.

“The mine and the concentrator are operating at 100 percent capacity and we have been operating like that for a month now. We have a stockpile for the concentrator which has been running for the past week now. This means we are building stockpile for the smelter which will resume operations in June and it will be operating at full capacity as well. We came into this year with big plans just like any other organisation but in January and December we were not sure of what was heading our way and we are seeing the effects now.

“We closed down when the full lockdown was implemented. We were then given a waiver to restart on April 7. Then we resumed mining but the concentrator and the smelter remained closed. On May 1 we restarted the concentrator and our intention is to restart the smelter on June 1. Our view has been that this is not a sprint but a long marathon therefore we need to be careful,” he said.